Etorki, in collaboration with BRAUN (Austria) and Silvercut (Germany) offers the widest range of abrasive cutting off machines for the industry.

From laboratory specimen cutting equipment to slitting machines for continuous casting slabs in steelworks; discs from 200 mm to 2.000 mm in diameter.

We are specialized in stationary abrasive disc cutting equipment for steel and other metal parts and we will study your process to propose the ideal solution.

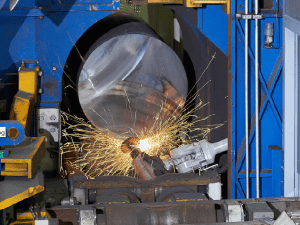

Abrasive cutting is the ideal cutting technology for many applications in the metal sector. It can be used for cutting cold, warm or hot products.

Designs and manufactures abrasive cut-off discs up to 2.000 mm diameter.

It also has mixed installations of two types of discs (abrasive disc and friction saw – with carbide inserts) so that the abrasive cuts high strength materials and the friction discs cut std. grades of material.

Individual turnkey solutions, all auxiliary installations included.

Some advantages of abrasive cutting are:

< Guarantees the shortest cutting times,

< High automation capability

< Reduced total operating costs

< Cutting of all types of profiles and materials

Silvercut has more than 40 years of experience in the field of cutting and is dedicated to the metallographic industry for the cutting of specimens, as well as productional cutting of parts with guides, tubes, ball screws, spindles, medical implants or equipment for lost wax casting.

Their abrasive cutting equipment and tools enable fast, efficient and safe material processing of the following materials: high-strength steels, composites, glass or carbon fiber, cast iron, aluminum…

Here below we show the remaining range of cutting equipment (from 200 mm to 600 mm) from Silvercut. Ask for further information for any customized order.

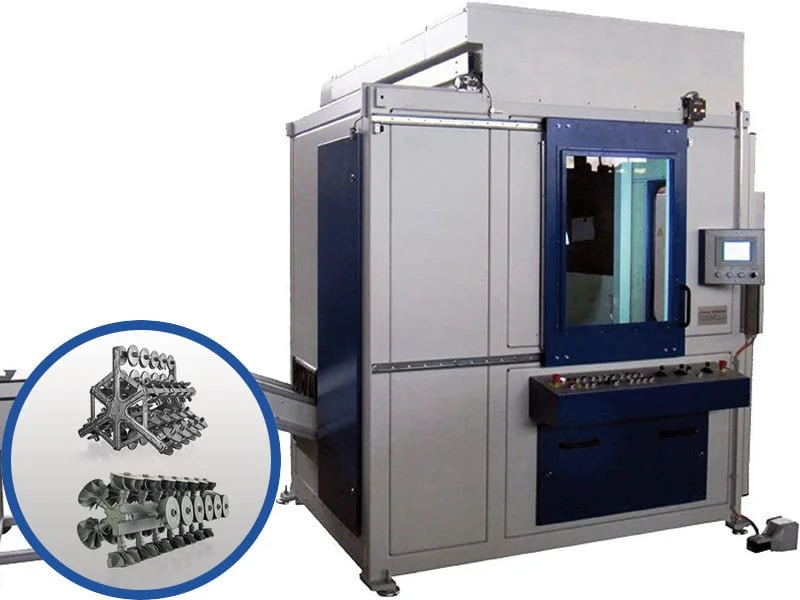

Cutting equipment (dry and wet)

< Cutting of guides, spindles, ball spindles, bars, profiles… in both pendulum and oscillating systems.

< Automatic cutting with manual or automatic feed, dry cut or with drill, with a disc of 200 mm to 600 mm.

Investment casting

< In the dry separation process the ordered wax parts are separated from their cluster. The equipment can be manual, semi-automatic or automatic, and commonly the parts hang from their own casting channel.

Metallography

< In the field of destructive testing, we offer wet cutting equipment for cutting high strength steels, ceramics and composite materials.

< Jaws and pads of our own design are some of the advantages for the laboratory cutting of any section.

< Table-top equipment (automatic and manual) as well as stationary equipment for medium and large parts.

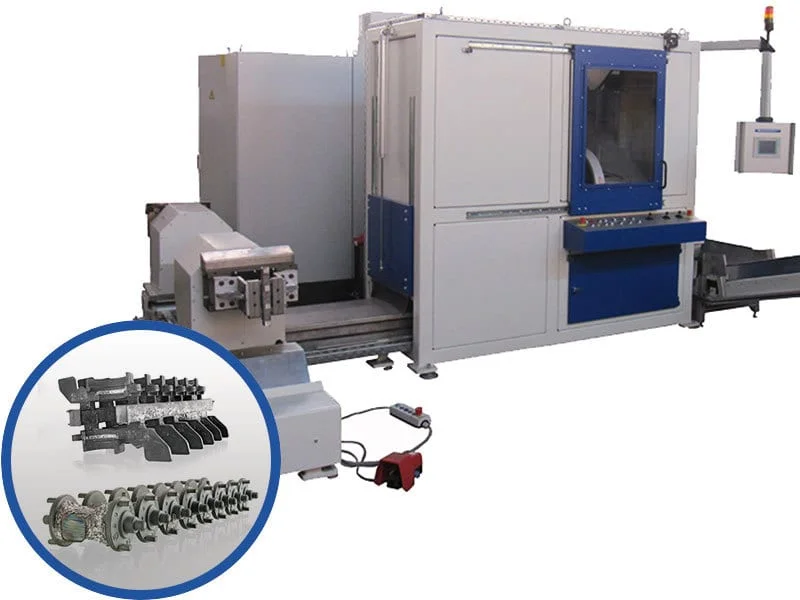

Cut to length equipment

< With Silvercut’s tailor-made equipment, even the most special parts made of any material can be cut in a cost-efficient way.

< Clamping and feed are tailored to the customer’s needs. Discs up to 600 mm.

Do not hesitate to contact us

Contact us if you require further information about our products and services. Feel free to call or write us using our contact form and our team will get in touch with you.