The grinding wheel according to its operation, from the initial roughing of the metal to the exit of the continuous casting until lapping. Our specialty since 1978. All combinations of grain or binders (resin, vitrified or cork-rubber).

Grinding

We have more than 35 years of competence in the application of these wheels, which gives us the hability of satisfying the most demanding needs of the industry.

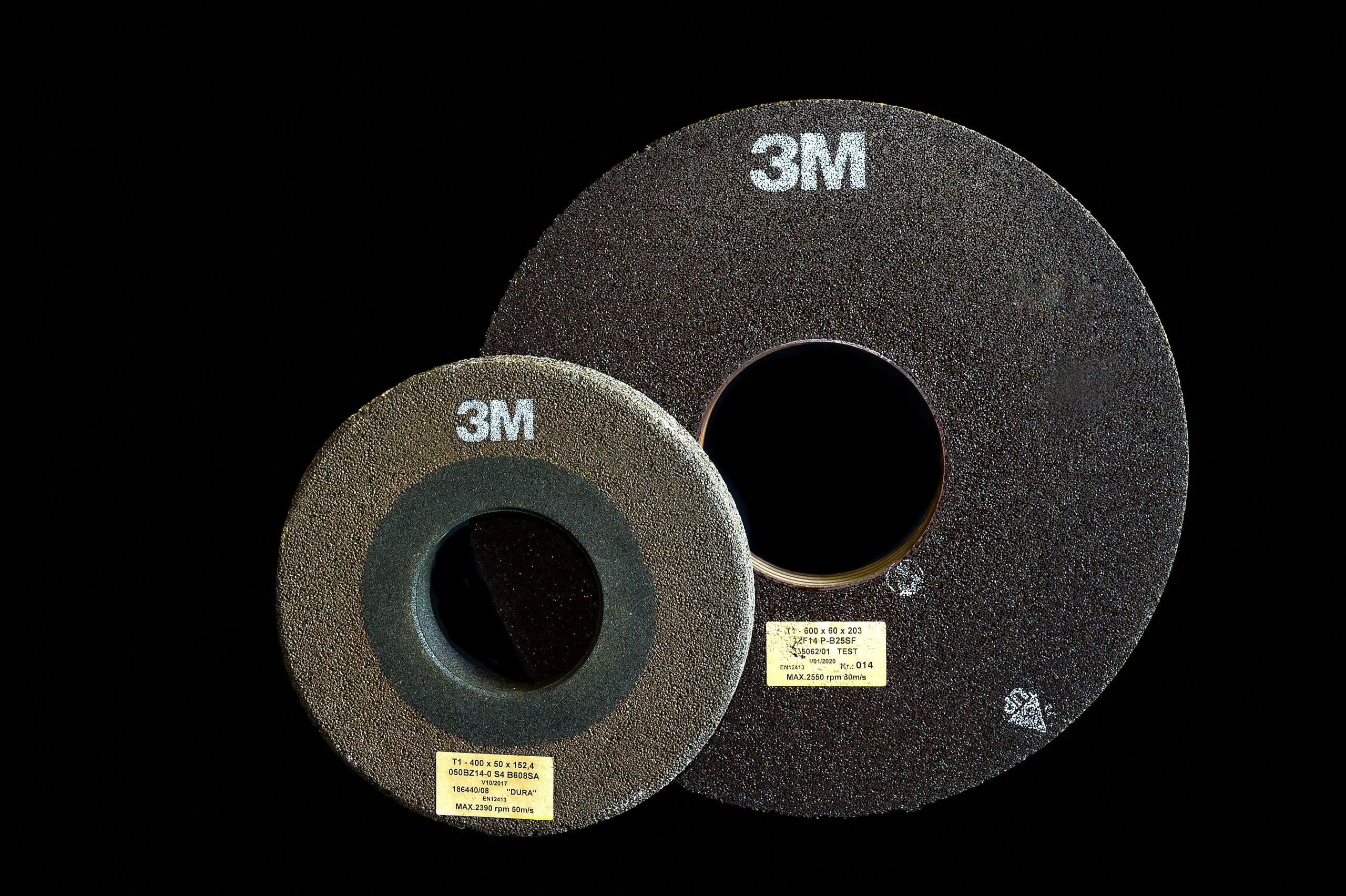

Hot pressed grinding wheels for surface conditioning of slabs, blooms, ingots, billets, bars, electrodes and thick-walled tubes in automatic high-pressure grinding machines.

Grinding is used to remove surface defects, husks, decarburization and cracks originated in the production process.

For optimum product performance, the right combination of abrasive, grit size and bond must be used.

Coarse-grained grinding wheels (#8-24), mixed zirconia aluminium oxide and different types of resin-bonded rods, can have chopped glass fibre to reduce the heat generated in a heavy-duty operation as well as glass fibre reinforcement fabrics, always reinforced with steel rings in the core.

In addition, Etorki will manufacture to your requirements once our technicians have studied the conditions of the application.

Cylinder grinding

Etorki designs, to your needs, conventional and last generation grinding wheels with PSG grain, 3M CUBITRON II, both resin and ceramic bonded grinding wheels.

Grinding wheels for the manufacture of lamination cylinders, as well as those used for reconditioning cylinders in production, both in hot and cold rolling mills.

The grinding of rolling mill rolls is an operation of great importance, due to the presence of cracks caused by heating, wear and loss of material on the surface of the rolls.

Another complex process is the grinding of cylinders for paper mills, as we are working with very long and large diameter parts.

The types of grinding wheels most commonly used in this application are: resin and ceramic bonded for the roughing operation and rubber-cork bonded for the finishing operation.

Deep grinding (Creep Feed)

Custom grinding wheels for the aircraft and gas turbine industry.

Creep feed grinding is characterised by a high depth of cut per pass and a low feed rate into the workpiece.

Creep feed has many advantages over reciprocating grinding, such as a higher stock removal rate, greater ability to maintain shape, etc.

These advantages, however, come with other demands, such as much higher forces and temperatures, which the grinding wheels have to withstand.

Centerless bar grinding

For this application we recommend SIAPI branded grinding wheels, in resinoid binder for roughing and in cork-rubber binder for semi-finishing and finishing.

The rubber is able to absorb the micro-vibrations generated by the machine and guarantees an excellent surface roughness avoiding the optical spirals of the pieces coming out of the machine.

Long life is guaranteed by the self-reviving effect of these wheels, together with a narrow range of finish, roundness and dimensional tolerance.

The differentiated grain technology allows to combine roughing and roughness by reducing the number of passes, thus saving both manpower and energy.

Once the processes implemented in the production lines analysed, our centreless grinding technicians can design grinding wheels to suit your needs and reduce the cost/part ratio.

Different materials can be processed depending on the specification: tempered steel, chrome-plated steel or stainless steel.

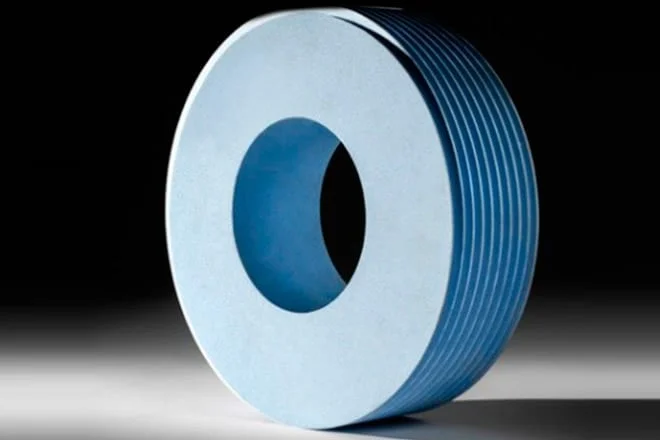

Precision centerless grinding

THROUGH-FEED

Centerless through-feed grinding with combined grinding wheels, an infeed zone for roughing with high cutting capacity and an outfeed zone for achieving the required surface finish.

Combinations can be made with ceramic and/or resinoid and/or rubber grinding wheel parts.

We seek a balance between the different binders and grain sizes to achieve results with a self-reviving grinding wheel which does not clog up and generates a cold and clean cut, as well as an adequate surface finish.

For the needle roller and shaft bearing manufacturing industry.

PLONGEE

Customized grinding wheels, usually made with ceramic grinding wheel in one piece, making it possible to manufacture grinding wheels with different zones (grain size and hardness) to achieve different surface requirements in one piece.

Diameters up to 760mm for larger widths the joint is made obliquely, so that we minimize the surface difference generated by the joint.

The machining on the grinding wheel of the working preform is optional, minimizing the changeover time and the consumption of the diamond dresser.

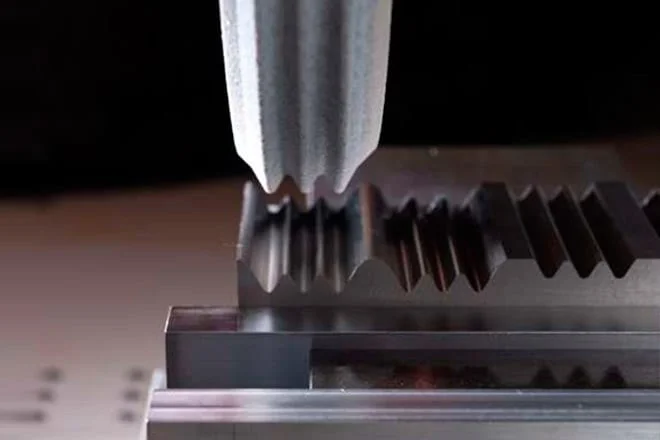

Gear grinding

For the gear machining after heat treatment, we offer customized grinding wheels in ceramic bond which allow an excellent finish of the surface combined with a high stock removal.

These grinding wheels are particularly suitable for all applications where very close tolerances are required. They are available in two versions: profiled (according to customer drawings) and unprofiled.

For spiral bevel gear grinding and continuous generation grinding.

Once the processes analysed, our technicians can design customized grinding wheels and reduce the cost/part ratio.

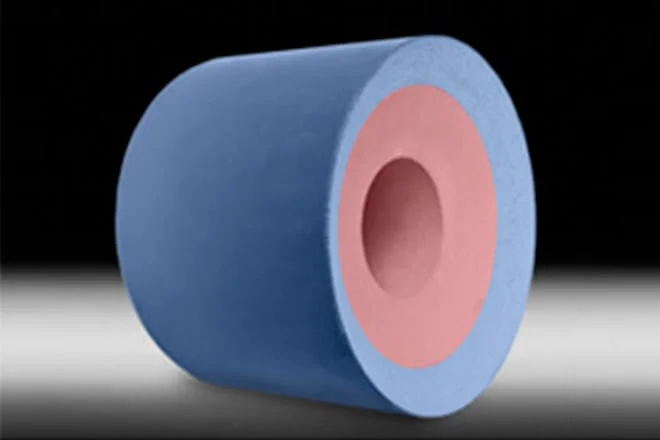

Grinding of tapered rollers

We have a range of specific SIAPI products for applications in the bearing sector, from diameter grinding to head facing.

Manufactured from innovative raw materials, rubber bonded grinding wheels guarantee excellent results.

In the grinding of tapered rollers, as the regulating wheel is made of steel, the rubber absorbs micro-vibrations, guaranteeing an excellent surface roughness.

In many applications, they are fully self-relieving and they guarantee a narrow range of finish, roundness and taper.

They are grinding wheels with an exclusive trailing edge technology, which allows the roller to be removed from the grinding zone, avoiding vibrations that would otherwise generate optical spirals.

The technology of differentiated grains allows to combine roughing and roughness allowing to reduce the number of passes. All of this translates into fewer setups being used, saving both personnel and energy, as well as cost per part.

For this particular application,recommend the use of rubber binder wheels for grinding and a rubber-cork mixture for finishing.

Cast iron roughing

Removal of defects originated in the foundry casting process is a fundamental work in the preparation of the product.

Etorki manufactures customized grinding wheels for deburring cast components in pendulum and pedestal machines.

Max. diameter 600 mm.

In most of the mixtures, zirconia aluminium oxide grains are used, which allow for higher stock removal, shorter grinding times and longer wheel life.

Mounted points with rod

Complete range of sizes and shapes, manufactured on demand according to the needs of each customer.

Abrasive grains in all qualities: white, pink, ruby and blended corundum.

- Grains: #20 to #100

- Rod: Ø 3 mm, 6 mm and 8 mm x 40 – Special length on request.

We manufacture in vitrified and resin binders, special for foundry.

Etorki is present in all operations: work on joints, grinding, levelling, deburring, surface treatment, edge machining (chamfering and rounding), edging, sharpening, weld removal.