Diamond tools for industrial use, all sectors: mechanics, aeronautics-wind, graphite, paper-cardboard, cutlery, pipes….

Metal, resin, or hybrid bonding wheels

- Premium grinding wheels

Etorki diamondCBN, a complete PREMIUM range of metal, resin or hybrid bonding wheels, specifically targets the manufacture and the sharpening of cutting tolls -both in tungsten cabide and high speed steel- on CNC and manual machines.

Resin bonding wheels are developed for dry or wet sharpening of hard metal and high speed steel tools.

The complete range of resin binders allows to obtain the best performance in each operation, adapting to the different parameters of stock removal per pass, grinding wheel speed and feed rate.

Metal binders allow reprofiling when the tool has lost its profile.

They are generally used wet. They are characterised by their excellent cutting quality, high wear resistance and high capacity to maintain dimensions and profiles.

Hybrid binders allow for maximum versatility and a great balance between tear-off capability and profile preservation.

They are designed to perform deep grinding/flute grinding operations on carbide and high speed steel (HSS) parts and tools on CNC machines, always with coolant.

- Bollards with shank for indoor use

The type of binder to be used will depend on the material to be ground.

They can be manufactured in diamond for tungsten carbide operations or in CBN for high speed steel.

- Diamond and CBN discs

Resin bonded discs are mainly used to cut hard materials with minimum wear and very good cut finish. In order to suit each operation and to achieve the best performance, it is also possible to manufacture discs in other binders

The superabrasive to be used for tungsten carbide should be diamond whereas for high speed steel it should be CBN, generally above 52 HRC.

Vitrified CBN

Vitrified binder is the answer to high speed grinding (> 80 m/s).

Extremely hard, it combines the best characteristics of metallic and resin binders. It guarantees a longer wheel life and works efficiently and productively, which is essential for maximum performance and minimum maintenance.

The most common applications for vitrified CBN grinding wheels are the grinding of automotive components, such as camshafts, CV joints, valves, gearbox shafts, etc.

Diamond cutters

Etorki has a complete portfolio of diamond dressers, extraordinarily competitive in quality and price.

Static

Monopoints, cut diamonds, conglomerates, tiles, roulettes, grinders, grinding handles for machines that do not have it incorporated.

Dynamics

High-precision diamond dressers or diamond knurling wheels developed with two manufacturing methods:

- Direct electrolysis (G+): They are generally used for grinding conventional wheels as well as vitrified CBN wheels. In its production the diamond is deposited by chemical electrolysis on the body of the knurling wheel that already has the desired profile. In this case the deposition is performed randomly in a single layer. The diamond is then ground to the desired tolerances. It is an economical solution, which allows to obtain a good tolerance and a high cutting capacity. It is normally used for short series.

- Reverse electrolysis (G-): It is generally used for grinding conventional wheels. In this case the diamond is not deposited directly on the roll but on a graphite mould by means of reverse electrolysis. As in direct electrolysis, the diamond is deposited randomly and in a single layer. Finally, the diamond is ground to the desired tolerances. This type of knurling wheel allows excellent tolerance to be achieved on very small profile radii, both concave and convex.

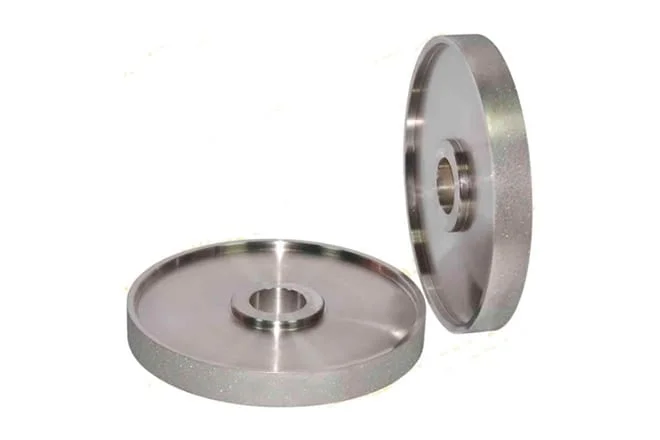

Electroplated grinding wheels

These wheels have a layer formed by electroplating in nickel baths, which allows the abrasive to be bonded to the metal surface. They are manufactured with a single diamond layer and high concentration.

Electroplated grinding wheels have excellent stock removal, high resistance to deformation and can be manufactured in complex and very precise profiles.

Recommended for materials such as plastics, composites, fibres (aeronautical and wind energy sector), foundry steels, friction materials, automobile transmissions, etc…

Flexible

Superabrasives applied on various flexible substrates:

Belts, discs, shank brushes, core brushes, lamellar discs, blocks and hand pads, diamond blades, quick-change discs, sleeves etc.

Do not hesitate to contact us

Contact us if you require further information about our products and services. Feel free to call or write us using our contact form and our team will get in touch with you.